What is stretching?

Elongation (stretching: positive elongation or compression: negative elongation) is when the shape of a body changes due to the influence of force (tension/compression), heat, cold or residual stress.

To determine strain, the relative change in length on a component is measured using strain gauges. In this process, the strain, i.e., the extent of the changes in the length of the component, is expressed as a percentage relative to the original shape.

How does a strain measurement work?

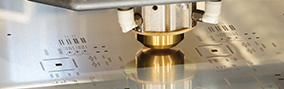

Strains can be represented by various measurement methods. Today, electrical and optical methods are commonly used. TEPROSA offers exclusively electrical strain measurements, where we use metallic strain gages (metallic strain gages/foil strain gages).

The principle of strain gages is based on the “Thomson effect“, which describes the proportional change of electrical resistances to strain. The core of the metallic strain gauges consists of a measuring grid that deforms when the resistance of the material changes.

These deformations or changes in length that occur due to the change in resistance can be measured and represented as strain, taking into account the correct proportionality factor (k factor). The change in length is divided by the original length of the object and expressed in micrometers per meter.

Where and when are strain sensors used?

Strain sensors are used in strain measurements as part of experimental stress analysis or mechanical fracture tests to measure residual stresses occurring in the material and determine its modulus of elasticity.

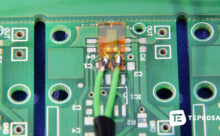

The aim of the measurement is often to stress the material. For this purpose, so-called foils DMS (metallic strain gauges) are prepared accordingly and applied in the test laboratory or at the customer’s site to the components to be examined.

The actual measurement is then carried out under load, e.g. during depaneling or another manufacturing step that is to be part of the investigation.

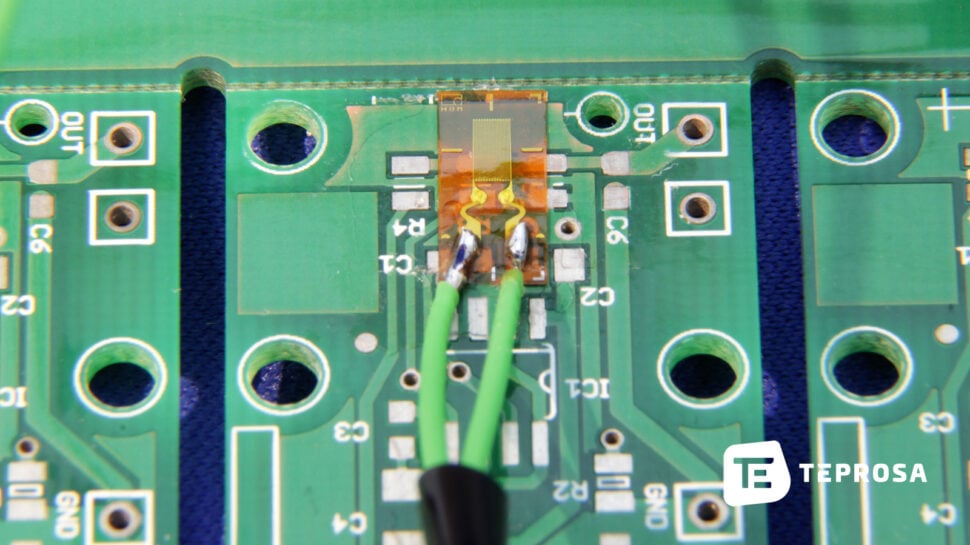

Strain measurement in printed circuit board assembly

A frequent application of strain gages or strain measurement using strain gages is the determination of strain loads in the manufacture of printed circuit boards and electronic assemblies or during their operation.Precise knowledge of the mechanical stress that occurs during assembly or depaneling enables optimization of the manufacturing parameters and thus a reduction in scrap during production. The same applies to the assembly of the modules.

Strain measurements on printed circuit boards according to IPC/JEDEC-9704A

The IPC/JEDEC-9704A makes clear specifications regarding permissible strain rates for many applications and the procedure for measuring stress using strain gages and calculating board strains.We specialize in strain measurement on printed circuit boards using strain gages, and for many years have been performing measurement jobs to detect strains in our customers’ manufacturing environments directly on the machines used for manufacturing. With our help, you can meet the standard and improve your manufacturing processes.

Advantages of mechanical strain measurements?

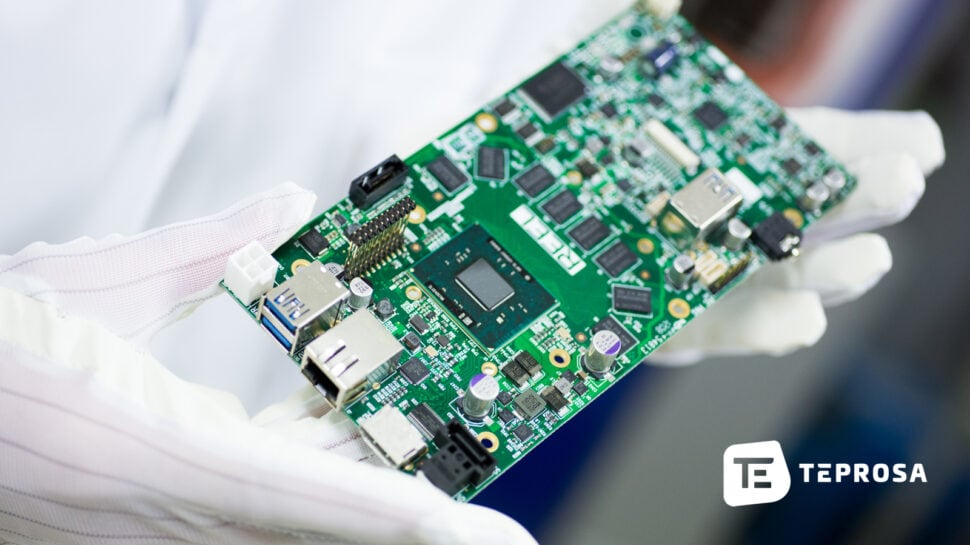

With strain sensors, even very small changes in shape can be detected and stresses can be determined precisely and with a high degree of accuracy. The principle of strain measurement with strain gauges makes the application very flexible, since the strain gauges can be applied to various materials even in the smallest installation space.

We use only certified measurement technology and carry out measurements in our laboratory or on site at our customers. The results of the measurements are presented in a comprehensive report. Of course, we are available to discuss the results and provide further advice.

Our quality management

As a conscientious testing laboratory for environmental simulations and component analysis, we have set ourselves the goal of performing tests with the highest quality standards and exclusively using certified measurement technology.

To achieve this goal, we work within the framework of our Quality Management System according to clearly defined processes, which we constantly review and develop. For us, quality refers to all business processes. You can find more information about our QM system and processes here.

Further services in our Testing & Checking division

As a testing laboratory specializing in electronics and electromechanical assemblies, we offer not only the application of strain gauges but also a wide range of other tests for damage and component analysis through to the complete validation of electronic assemblies.