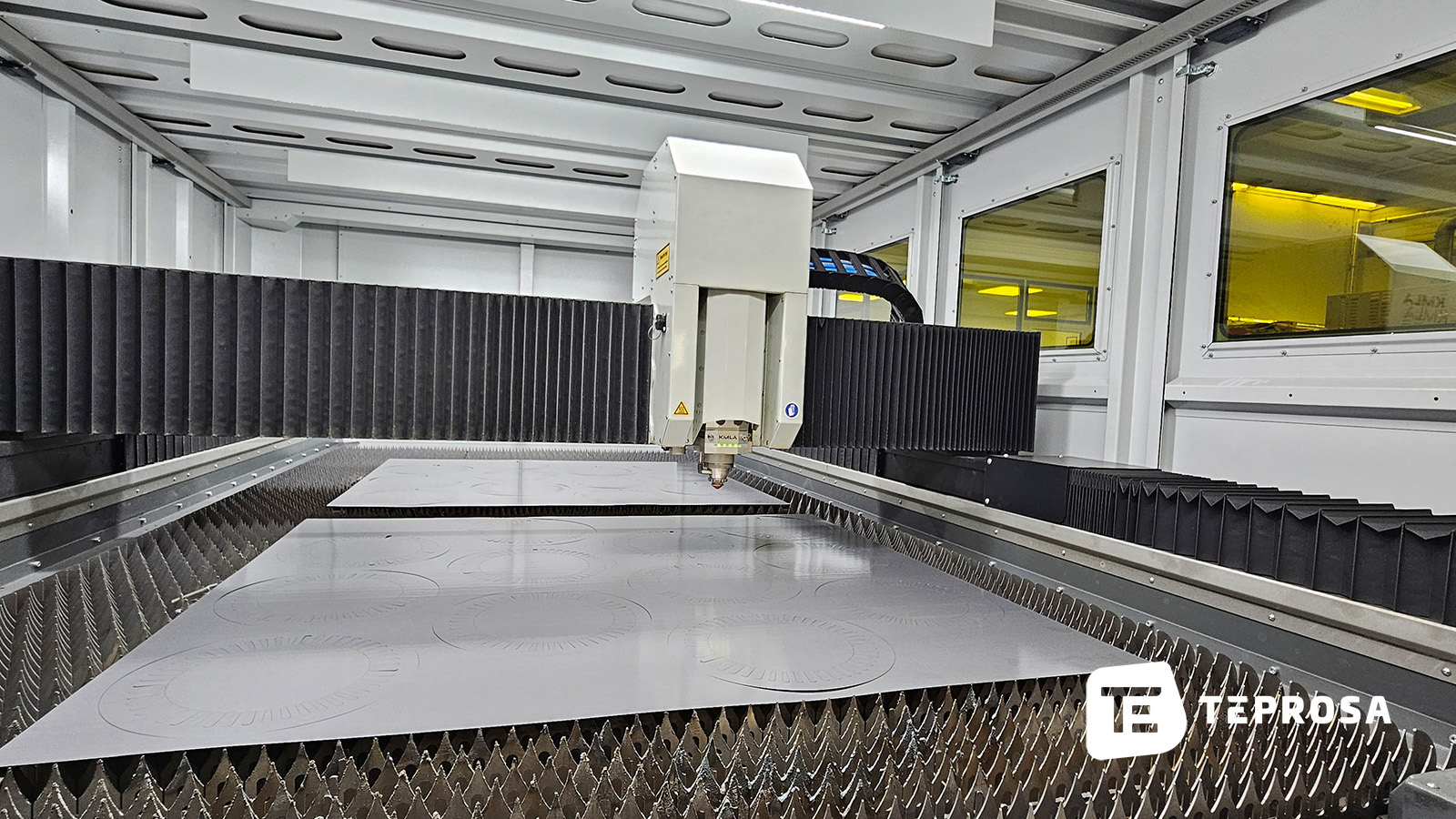

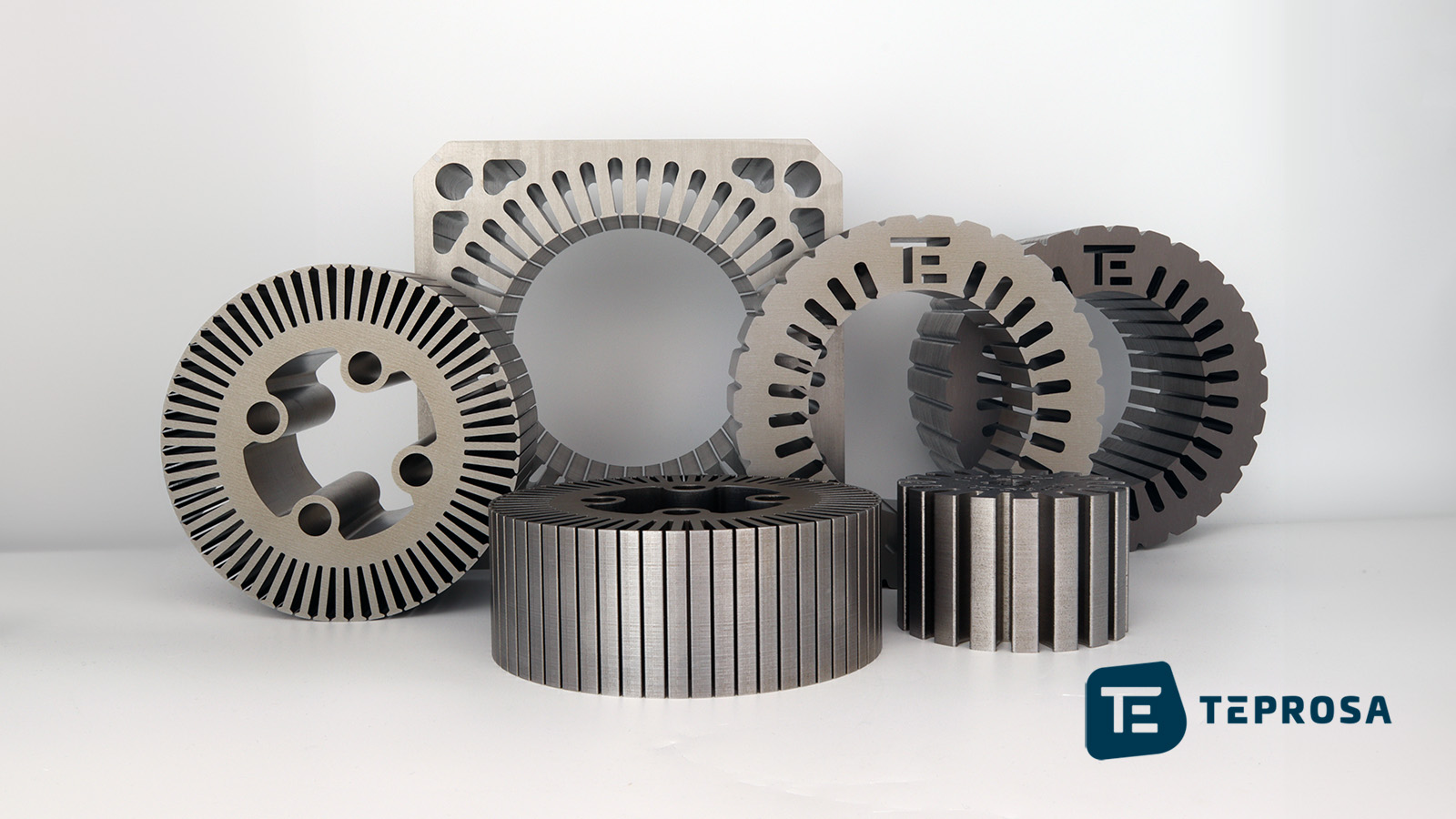

Die TEPROSA GmbH wurde 2009 gegründet und hat Ihren Sitz in Magdeburg. Mit über 20 Mitarbeitern bieten wir als Hersteller und Partner für Lasertechnik in Deutschland Lohnfertigung in den Bereichen Laserschneiden, Metall- und Blechverarbeitung und 3D-MID. Wir fertigen anspruchsvolle Laserteile mit höchsten Qualitätsstandards für die Automobilindustrie, die Medizintechnik, den Maschinenbau und viele andere Branchen. Zu unseren Produkten gehören Elektrobleche für Elektromotoren, Zuschnitte für Automobil und Industrie, sowie präzise Abstimmplatten für Kunden aus der ganzen Welt.

TEPROSA bietet als kompetenter und innovativer Auftragsfertiger verschiedene Fertigungsprozesse und Prüfdienstleistungen in den Bereichen Elektroblech, Laser-Bearbeitung (Laserschneiden und Gravuren), 3D-MID und dem Testen und prüfen elektromechanischer Baugruppen.

Wir fertigen seit unserer Gründung 2009 anspruchsvolle Produkte mit höchsten Qualitätsstandards für die Automobilindustrie, die Medizintechnik, den Maschinenbau und viele andere Branchen.

Mehr erfahren

Wir haben uns das Ziel gesetzt, Produkte mit höchsten Qualitätsansprüchen herzustellen. Um dieses Ziel zu erreichen, arbeiten wir nach klar definierten Prozessen, die wir ständig überprüfen und weiterentwickeln.

Qualität bezieht sich für uns nicht nur auf Produkte, sondern auf alle Geschäftsprozesse.

Mehr erfahrenWir legen großen Wert auf ein kooperatives Miteinander und die Qualität unserer Arbeit. Verantwortungsbewusstsein, Zuverlässigkeit und Loyalität gegenüber unseren Kunden und Geschäftspartnern zählen zu den Werten, die unsere Unternehmenskultur prägen. Deswegen haben wir uns das Ziel gesetzt, Produkte mit höchsten Qualitätsansprüchen herzustellen.

Mehr erfahren