ABOUT US

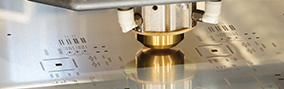

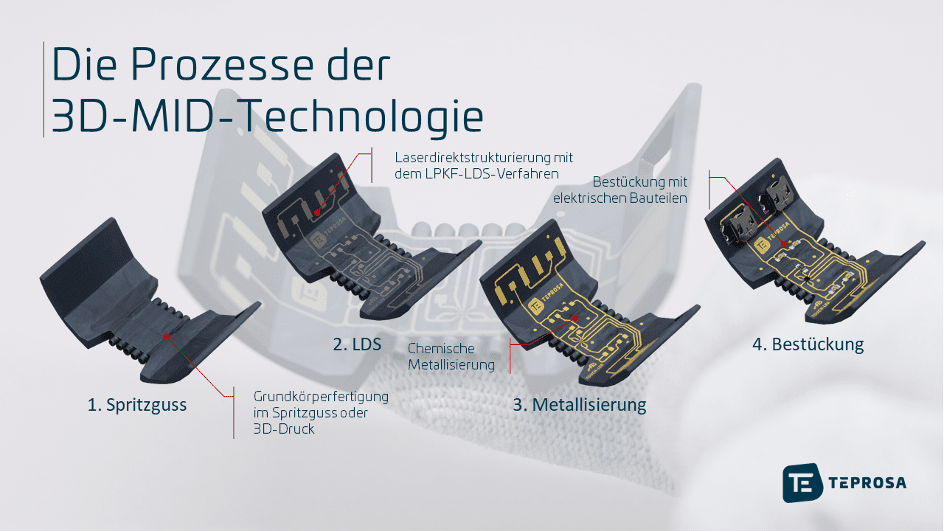

As a competent and innovative contract manufacturer, TEPROSA offers various manufacturing processes and testing services in the areas of laser processing (laser cutting and laser engraving), 3D-MID and the testing and inspection of electromechanical assemblies. Since our founding in 2009, we have been manufacturing sophisticated products with the highest quality standards for the automotive industry, medical technology, mechanical engineering and many other sectors.

Our customers

Satisfied customers are important for the sustainable success of our company and the best advertisement for future cooperation. We are therefore happy about the successful cooperation with our partners – these include well-known companies such as Siemens, Volkswagen, Olympus, Dräger, Carl Zeiss and many more.

BUSINESS FOUNDATION

TEPROSA GmbH was founded in 2009 as a high-tech start-up from the Otto von Guericke University in Magdeburg. The origin of the success story was the InnoProfile project TEPROSA, a technology platform for product miniaturization in Saxony-Anhalt. The aim of this project was to set up a platform for regional SMEs and to develop and promote new processes in the field of assembly and connection technology (packaging), microsystems technology (MEMS) and injection molding technologies for the construction of spatial circuit carriers (MID).

QUALITY & PHILOSOPHY

We put great emphasis on cooperative interactions and ensuring our work’s quality. Responsibility, reliability, and loyalty towards our customers and partners characterize our corporate culture and belong to our core values.

QMS ISO 9001:2015

In order to meet the demands we place on ourselves and the requirements of our customers, we have established a quality management system in accordance with DIN EN ISO 9001. Since 2013 we have been working according to clearly documented processes and thus ensure the complete traceability of our products. In the field of 3D-MID, TEPROSA has been one of three German companies since 2015 that are certified as “Authorized LDS Manufacturer”. As a member of the 3-D MID e.V., TEPROSA supports the further development of the technology.

We work with a quality management system according to DIN EN ISO 9001: 2015. Here you will find our current certificate.