Get your individual offer for steel plates in 3 steps

Welcome to TEPROSA – your reliable partner for high-quality, laser-cut steel plates and steel discs, plate packs and plate sets made of steel for precise clutch systems.

1. Choose your material

2. Upload technical drawing

3. Provide contact details

Phone: 0049 (0)391 598184 70

E-Mail: anfrage@teprosa.de

» Material for steel plates

A variety of materials are suitable for laser cutting steel lamellas and steel discs. Here you will find an overview of the materials we process at TEPROSA:

Sheets and foils:

- Stainless steel, stainless steel foils

- Aluminum, aluminum foil

- Copper, copper foils

- Brass, brass foils

- Nickel, nickel foils

- Steel, steel foils

We have a large selection of materials available in stock. We are also happy to process material you have provided, or procure materials from our long-term, experienced suppliers according to your specifications and wishes. The delivery of corresponding material test certificates for your laser parts is possible at any time after consultation.

For a detailed overview of the most common materials, it is worth taking a look at our materials overview.

» Manufacturing conditions for steel lamellas and steel discs

- Minimum kerf width/minimum spot diameter: 0.03 mm*

- Repeatability ±2µm

- Micro-webs from 0.03 mm (small connection between contour and sheet metal to anchor the cuts in the sheet metal composite)

- Cutting speeds up to 50mm/s

- Cutting gas support up to 25 bar

- Nitrogen

- Oxygen

- Compressed air

- Contour accuracy: ± 0.01 mm*

- Holes from 0.03 mm

*depending on the material/material and its material thickness

» Short delivery times – optional express production

We have many materials of different material thicknesses available in stock for laser cutting of steel clutch plates. As a manufacturer, we are able to process your laser request within a very short time. We produce batch sizes starting from one and offer optional express processing for many orders within one working day.

- Express processing, optionally within one working day

- Large series > 1 million parts/year

- Prototypes from quantity 1

- Special materials available at short notice upon request

Free samples

If you would like to convince yourself of our quality in advance, we would be happy to send you free samples in advance.

» Information for buyers

We are specialized in business 2 businesst. Upon your request, you will promptly receive a written quote that takes into account all technical requirements. Here you will find further links and helpful information for buyers:

»Inquiry without CAD data

You can also place a request for laser cutting of steel lamellas and steel discs online without CAD data. Simply enter the geometric data and the desired material of your workpiece into our online inquiry form. Our experts will check your data and then contact you immediately so that we can provide you with an attractive production offer as quickly as possible.

» Confidentiality & data security

We guarantee the security of your data – if you still need a nondisclosure agreement in advance, you can >download our nondisclosure form here. We would also be happy to review your in-house agreement. To do so, please simply send it to us by e-mail at: einkauf@teprosa.de.

We take confidentiality and data security very seriously! If you would like to enter into a nondisclosure agreement, send us your form or download our template.

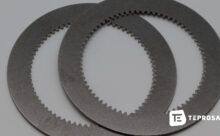

Steel plates for clutches – maximum performance, minimum tolerances

Welcome to TEPROSA – your reliable partner for high-quality, laser-cut steel plates and steel discs, plate packs and plate sets made of steel for precise clutch systems. Our steel slats set standards in terms of quality, durability and performance. We deliver individual laser-cut steel plates and plate packages for clutches according to your specifications quickly, easily and at an impressive price. Our laser systems cut steel and stainless steel up to a material thickness of 15 mm (some materials even beyond this) with the highest precision and accuracy (± 0.01 mm). Laser cutting is an economical and technically outstanding process for quickly and precisely processing sheet metal, metal foil and other plate-shaped materials.

OUR POSSIBILITIES

- Contours: according to customer specifications

- Material thickness: up to 15.00 mm

- Materials: steel / stainless steel, brass, copper, aluminum

- Final treatment: brushing, trovalizing, vibratory grinding

- Repeatability: ±2 µm

- Quantity: samples (from 1 part), small series, series