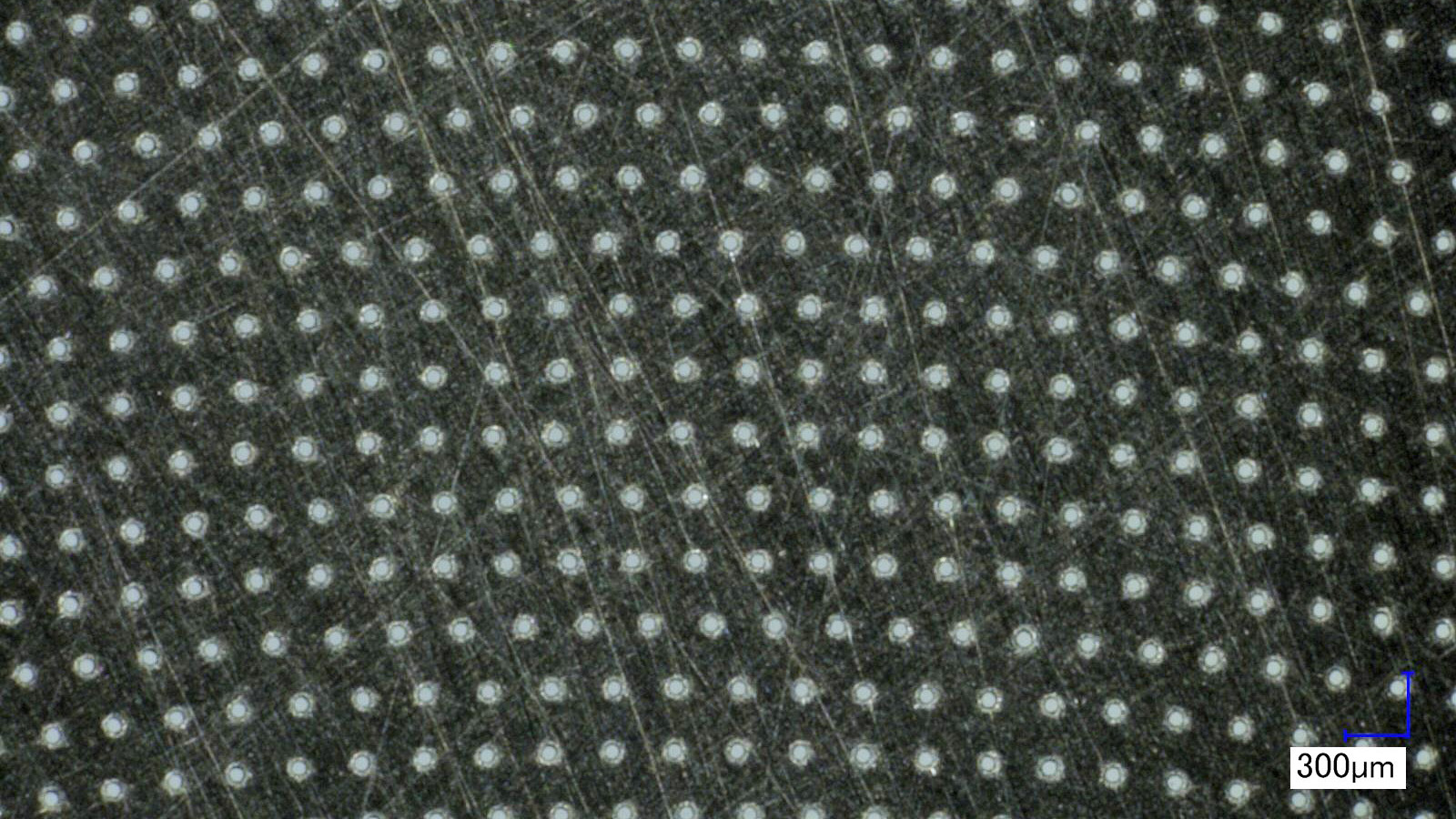

Laser drilling the smallest holes with the highest accuracy and quality

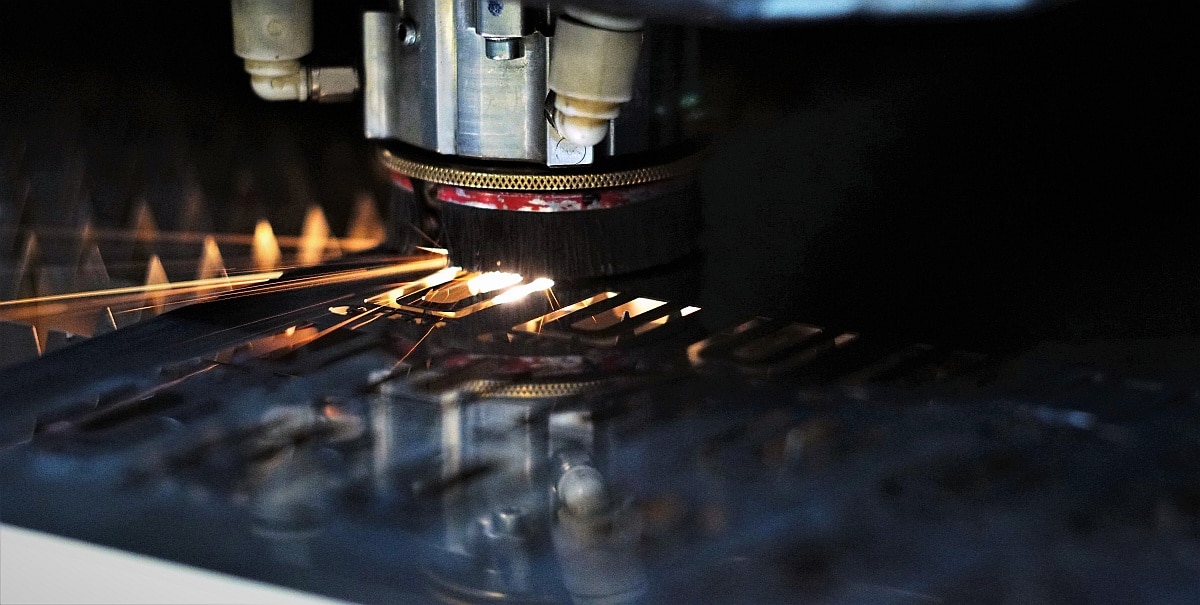

Laser drilling is a non-chipping drilling technique for producing fine holes in various materials and material thicknesses. Through the targeted use of pulsed laser radiation, the finest drillings in the micrometer range can be realized at high speed. We offer percussion drilling and single pulse drilling, two precise drilling methods for many applications.

.

When a hole is created by cutting through the material along the outer contour of the hole, it is referred to as laser cutting rather than laser drilling.

Telephone consultation: +49 391 598184 70

Email: anfrage@teprosa.de

Materials/materials for laser drilling

Many materials and materials are suitable for laser drilling. Here you will find an overview:

sheets and foils – material thickness: 0.02 mm – 6.00 mm

- Stainless steel and stainless steel foils

- Aluminum and aluminum foils

- Copper

- brass

- Nickel

- Steel

- carbon steel/carbon steel;

Other materials

- Ceramic (silicon nitride)

Manufacturing conditions

Our manufacturing conditions for laser drilling

- Minimum diameter: 0.03 mm*

- Up to 50 holes/s

*Depending on the material/material and its thickness.

Customized manufacturing & materials

We have a large selection of materials and materials with a wide variety of alloys available from stock. However, we are also happy to process material provided by you, or procure materials and materials according to your specifications and requirements from our long-term, experienced suppliers.

The delivery of corresponding material test certificates for your laser parts is possible at any time after consultation. For a detailed overview of the most common materials and materials, it is worth taking a look at our material overview.

Your material is not listed? Contact us. Our experts will be happy to advise you on material selection and technology options. If required, we will be happy to perform cutting tests with your desired material and give you a professional assessment of the suitability for laser processing of your material.

Information for buyers

As a service provider for the B2B sector, it is a matter of course for us to provide you with a written offer that matches your inquiry in accordance with our general terms and conditions. In doing so, we naturally also act for you as a long-term supplier. Here you will find further links and helpful information for buyers:

Request without CAD data

You can also place a request for laser drilling online without CAD data. To do so, simply enter the geometric data, as well as the desired material of your workpiece into our online request form. Our experts will check your data and then contact you immediately to provide you with an attractive manufacturing offer as quickly as possible.

Confidentiality & Data security

We guarantee the security of your data – but if you still need a non-disclosure agreement in advance, you can download our non-disclosure form here. We would also be happy to review your in-house agreement. To do so, please simply email it to us at: einkauf@teprosa.de