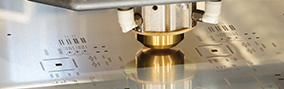

LASER CUTTING OF FINE AND THIN METAL SHEETS

We offer our customers laser cutting of fine and thin sheets, as well as laser fine cutting of materials with very low material thicknesses (0.20 mm – 4.00 mm) as contract manufacturing. Of course we manufacture from the first sample and also up to mass production. If you do not know whether your material is suitable for processing with the laser, we will be happy to find out for you and provide you with a first demonstration sample free of charge.

OUR CAPABILITIES

- Contours: according to customer specifications

- Material thickness: from 20 – 4,000 μm

- Materials: steel / stainless steel, brass, copper, aluminum, ceramics

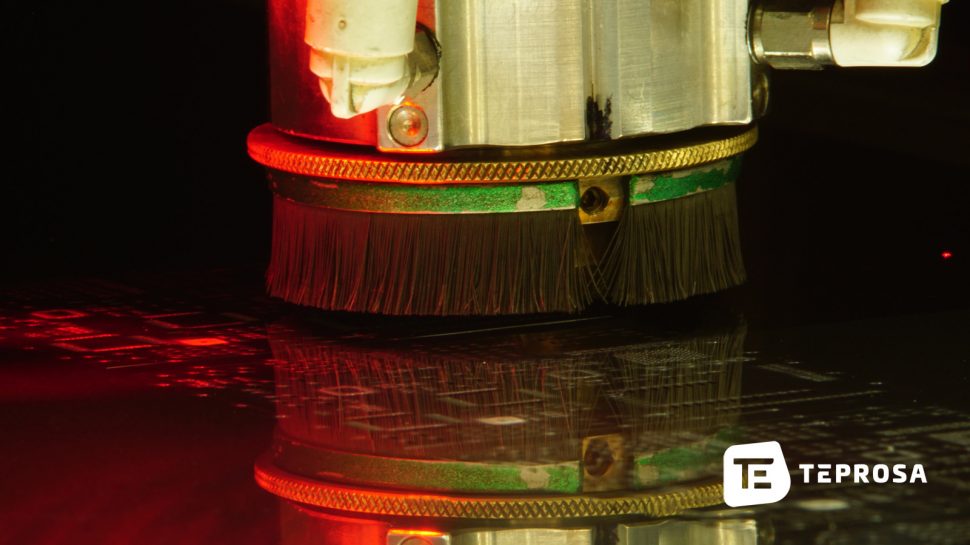

- Finishing: brushing, vibratory finishing, electropolishing

- Repeat accuracy: ± 2 μm

- Quantity: samples (from 1 part), small series, series

YOUR ADVANTAGES

- Great precision and tight tolerances at the highest cutting speed possible: economy

- Burr-free machining of 2D and 3D structures: no post-processing

- Flexible and short-term adaptation of the components possible: no tools required

- Suitable for samples, single pieces and small quantities: no set-up costs

JUST SEND US YOUR ENQUIRY DATA

Just send us your data and tell us the desired quantity. We will gladly send you an appropriate offer, or contact you if there is any need for clarification. Here we go…

WHICH MATERIALS ARE SUITED FOR LASER CUTTING?

In addition to steel and other metals (steel and metal foils), the choice of materials includes ceramics (silicon nitride), glass fiber reinforced plastics, composites and many more. We are happy to perform an appropriate parameter determination for your material and determine the suitability for processing with the laser.

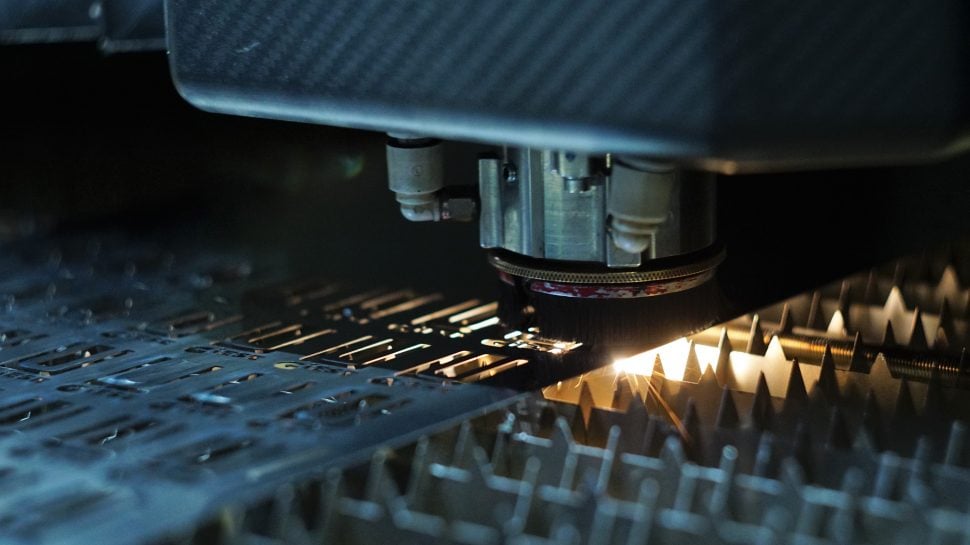

THE TECHNOLOGY

The gentle material processing with the laser is ideal for cutting stencils or precision parts made of thin metal foils. But also for the production of microstructures and microholes with exacting tolerances. Laser cutting with a repeat accuracy of ± 2 μm and a spot diameter of less than 30 μm offers many advantages, especially for the production of high-precision SMD stencils, calibration applications or precision mechanical parts. In order to comply with the highest quality standards, TEPROSA tests each laser-cut opening in real-time during processing in the laser. Deviations from the order data are thus recognized in the production process and the cutting parameters are adjusted immediately. This ensures consistent quality, prevents downtime and is more economical than a downstream manual or automatic optical inspection. Since laser cutting is a comparatively force-free production technique compared to competing processes such as punching, only a few burrs are formed in most materials. Should it be necessary, various proven techniques such as mechanical deburring through a brushing process are available for removing the burr , or electropolishing. On request, we will be happy to offer you corresponding post-processing processes.