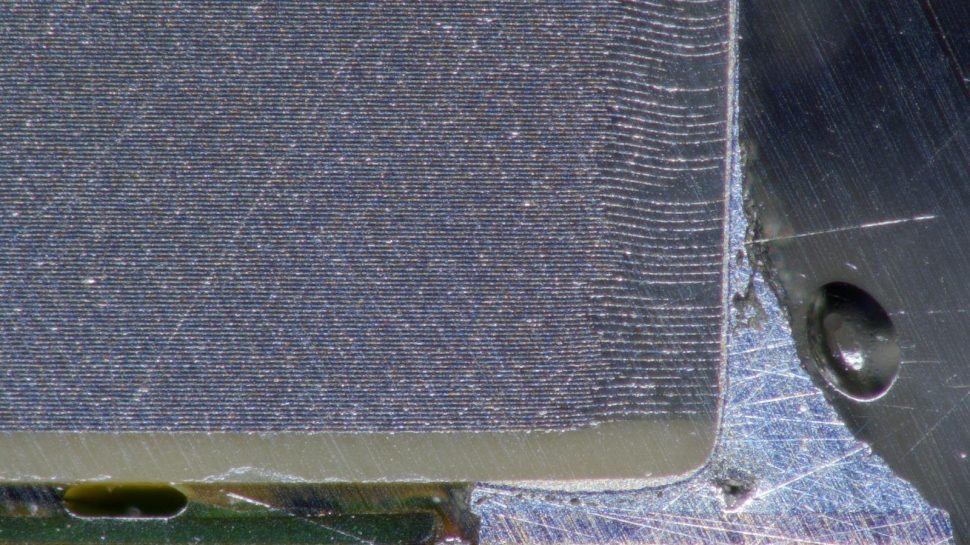

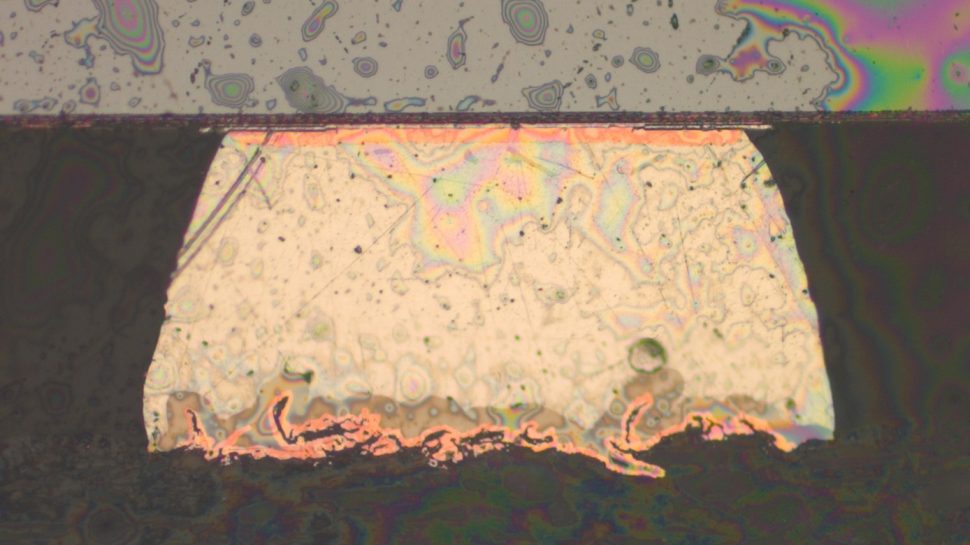

SHIELD IMAGE ANALYSIS AND MICROSCOPIC RECORDING

As a laboratory service provider, we offer micrograph analyses and microscopic images of electronic assemblies, crimp connections, joints and through-hole vias, among others.

We are happy to produce the corresponding micrographs in close consultation with you and evaluate the images according to the criteria and corresponding inspection plan agreed with you. We carry out the examination of the micrographs in our in-house laboratory and subsequently provide you with a comprehensive test report. You will benefit from our many years of experience in development, production and validation during the evaluation.

If desired, we can also offer you further examinations such as X-ray tests, shear or pull-off tests.

YOUR ADVANTAGES

- Quickly process your sample and generate a meaningful test report

- Evaluation possible based on agreed criteria

- Further testing and advice regarding damage prevention possible at TEPROSA

SIMPLY SEND US YOUR INQUIRY DATA

.

Simply send us your data and mark the desired grinding levels. We will be happy to send you an appropriate quotation, or get in touch with you if there is still a need for consultation. Let’s go…

FURTHER EXAMINATIONS

In addition to microsection analyses and microscopic images, we can also perform X-ray, REM and EDX analyses, among others, in our testing laboratory. Complete component validations or qualifications according to standards, specifications or customer requirements are also part of our portfolio. In order to support you in the clarification of damage cases and field failures and their prevention, we are also available to you following the damage & component analysis for a possible correction loop of your electronics and can, if desired, take over individual design optimizations or the complete redesign. Our services also include DMS analysis of mechanical assemblies according to IPC/JEDEC-9704A.