In 3 steps to your individual offer for iron cores

Select the desired material, the number of pieces as well as the sheet thickness. If you already have a technical drawing, attach it right away. Then we only need your contact details and we will send you an individual offer for your laser cuts! If you need multiple blanks, you can simply submit the order form several times.

1. select material

2. Upload file attachment

3. provide contact information

Telephone consultation: +49 391 598184 70

Email: anfrage@teprosa.de

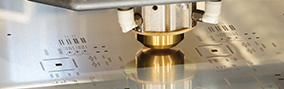

Electrical steel sheet is made of iron-silicon alloy and is divided into grain-oriented and non-grain-oriented materials. The starting material is manufactured as cold-rolled strip. It has special physical properties and belongs to the soft magnetic materials. Non-grain oriented electrical steel is classified by DIN EN 10106. A large number of standard grades exist for use in electrical systems, motors and machines. Here is an overview of the materials we process at TEPROSA:

- M235-35A

- M270-35A

- M330-35A

- M235-50A

- M270-50A

- M330-50A

- M530-50A

- M400-65A

- M800-65A

- NO20-15

- Other electrical steel grades on request

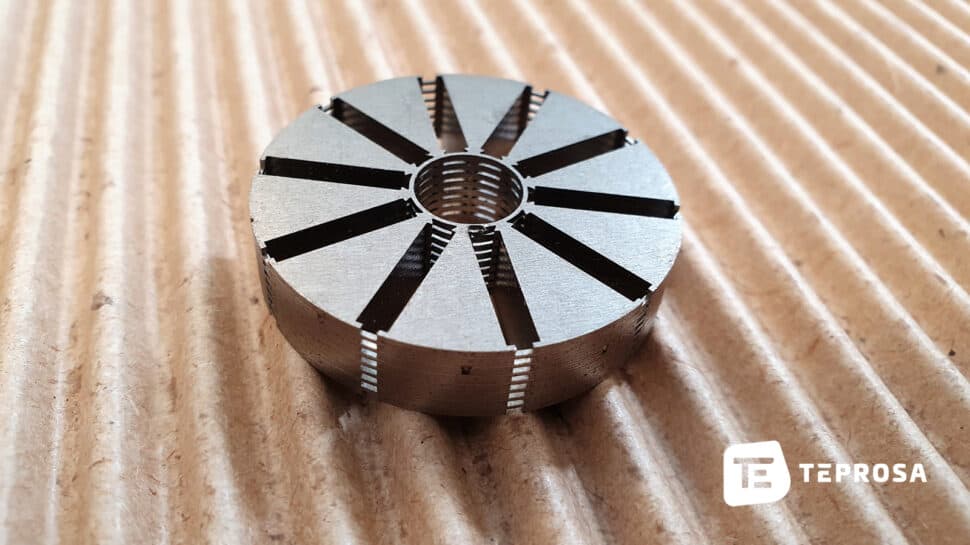

Our manufacturing conditions for laser cutting

- Minimum kerf width/minimum spot diameter: 0.03 mm*

- Repeat accuracy ±2µm

- Micro-bridges from 0.03 mm (small connection between contour and sheet to anchor the blanks in the sheet composite)

- Cutting speeds up to 50mm/s

- Cutting gas support up to 25 bar

- Nitrogen

- Oxygen

- Contour accuracy: ± 0.01 mm*

*Depending on the material/material and its thickness.

You do not find your material in our overview? We are also happy to process material provided by you or procure appropriate materials. On request, you will receive all materials with the corresponding material test certificate.

We are specialized in business 2 businesst. Upon your request, you will promptly receive a written quote that takes into account all technical requirements. Here you will find further links and helpful information for buyers:

We will gladly take over the data creation for you! Simply send us a corresponding drawing or the geometric data of your core sheet. Our experts will then contact you immediately.

We guarantee the security of your data – if you still need a nondisclosure agreement in advance, you can >download our nondisclosure form here. We would also be happy to review your in-house agreement. To do so, please simply send it to us by e-mail at: einkauf@teprosa.de.

We take confidentiality and data security very seriously! If you would like to enter into a nondisclosure agreement, send us your form or download our template.