Assembly validation (complete validation)

We perform environmental simulation tests and climate simulations for validation and qualification of electromechanical assemblies according to customer standard or specification requirements.

In doing so, any form of chemical, physical or other environmental impact on the product can be simulated by combining various individual tests. On request, we can implement electrical condition monitoring of the test items during the test according to your specifications.

> To online request

Temperature shock test (single test)

In a temperature shock test, test specimens are repeatedly subjected to defined temperature changes (so-called temperature shocks) in order to test the effects of the temperature changes on the test specimens.

TEPROSA offers a variety of specific tests we thermal shock (according to DIN EN 60068-2-14), cold (according to DIN EN 60068-2-1) or heat (according to DIN EN 60068-2-2).

> temperature shock test request

DMS application and strain measurement

In a strain measurement (also strain gage application or strain gage strain measurement), deformations caused by an elongation of the material are measured and made visible. This is also referred to as experimental stress analysis.

> Request strain gauge strain measurement

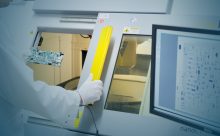

Damage & Component Analysis

In our test laboratory, we perform X-ray, SEM and EDX analyses, among others, to help you resolve damage and field failures. Following the damage & component analysis, we are also available to assist you in any corrective loop of your electronic assembly and can handle the complete rework/redesign if desired.

Our capabilities:

- X-ray testing

- Gauge strain measurement

- CT X-ray analysis

- X-ray fluorescence

- REM and EDX analyses

- Graph analysis

- Eveness and roughness measurement

- Shear and pull tests

- Contamination testing

- Tightness testing

- SIR test

- Electrical safety testing (dielectric strength, insulation testing)

Troubleshooting

Even before the damage has occurred in the field, we can help you troubleshoot your circuit.

Information for buyers

As a service provider for the B2B sector, it is a matter of course for us to provide you with a written offer that matches your inquiry in accordance with our general terms and conditions. In doing so, we will of course also act as a long-term supplier for you. Here you will find further links and helpful information for buyers:

Our quality management

As a service provider for laser fine machining, we have set ourselves the goal of manufacturing products with the highest quality standards. To achieve this goal, we work within the framework of our quality management system according to clearly defined processes, which we constantly review and develop. For us, quality refers not only to the products, but to all business processes. You can find more information on our quality management system and processes here.

Frequently asked questions about our testing procedures

About the process

1. What test procedures does TEPROSA offer?

a. Climatic/temperature bearings

b. Vibration testing

c. Temperature shock testing.

d. X-ray examinations.

e. DMS strain measurements.

f. Graph micrograph analyses.

2. What is meant by condition monitoring?

a. The measurement systems available in our test laboratory allow us to monitor, store and evaluate a wide range of electrical parameters during each cycle of the test.

3. Will I receive a test report?

a. Yes.

4. Up to what temperatures can the temperature shock test be run?

a. Tmax: 200°C

b. Tmin: -100°C

5. How large may the test specimens be for an environmental test?

a. The test chamber volume is 130l. The test chamber dimensions are 660x450x410 (TxWxH).

6. How heavy may the test specimens be for an environmental test?

a. Maximum test item weight: 25 kg.

7. Do I need to provide test fixtures?

a. No. We can offer you the manufacture of the test superstructures with pleasure.

8. How long does the processing of my order take?

a. This depends in the case of a component test very much on the scope and type of the / the test. In the case of complete validations, we need 4 working weeks for preparation.

This might also interest you

In addition to laser cutting, we also offer the following services: